MIL-DTL-22777G

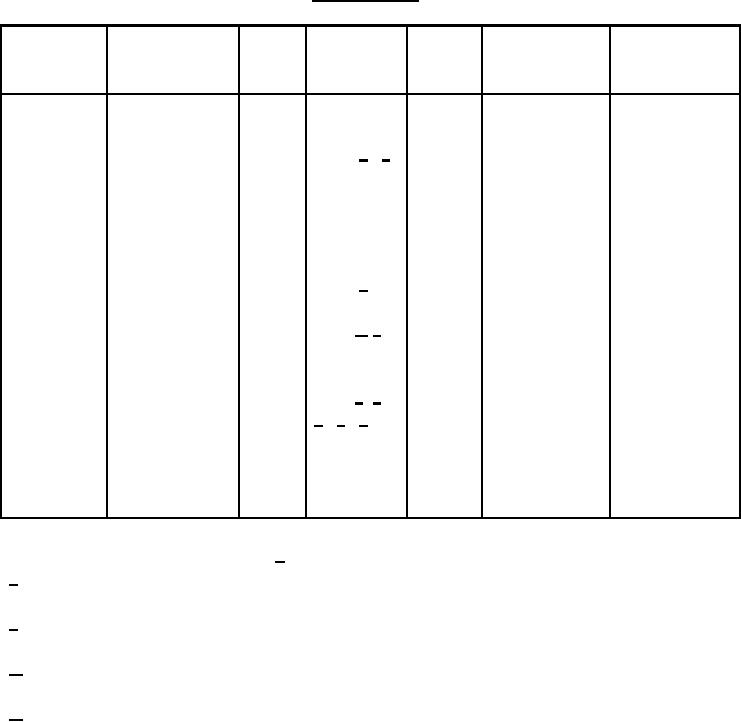

Table II - End item testing - continued

Number of

Rqmt.

Test

Sample

determinations

Results

Component

Characteristics

para.

Method

unit

per sample unit

reported as

Soles and

Cut growth

heels

After aging

3.2.1

ASTM-D-

X

2

Percent

1052 4/ 5/

Heels

Non-marking

3.2.1

4.6.1

X

1

Pass or fail

Soles

Stitch tear

ASTM-D-

Before aging

3.2.1

X

3

Nearest

4786 2/

pound/inch

ASTM-D-

After aging

3.2.1

X

3

Nearest

4786 1/ 2/

pound/inch

ASTM-D-

After

3.2.1

X

3

Nearest

4786 1/ 2/

immersion

pound/inch

3/ 4/ 5/

ASTM-D-

Tear strength

3.2.1

X

3

Nearest

624

Die C

pound/inch

1/ Aging shall be accomplished in accordance with Method 7221 of FED-STD-601. The soles and

heels shall be aged 24 hours at 212 + 1.8 o F.

2/ Buffing and preparation of samples shall be in accordance with ASTM-D-3183 and thickness

shall be in accordance with ASTM-D-624.

3/ The hole for the stitch tear test shall be made prior to immersion of the test sample in the test

fluid.

4/ The cut growth test shall be performed at full thickness of the sole and reported as percent of cut

growth after 50,000 cycles. A reading for each 100% increase in cut growth is not required.

5/ The specimens shall be clamped in the flexing machine and conditioned for one hour at 0° F

then run at 0°F, and the % cut growth shall be reported after 50,000 cycles. A reading after each

100% increase in cut growth is not required.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business